NC control PP41

it doesn’t always have to be CNC

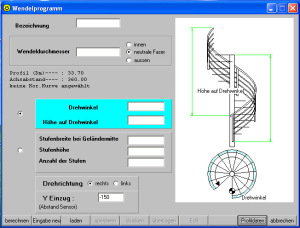

| The NC control type PP41 controls up to 3 axes. The control can be used with profile bending machines, universal bending machines and mandrel bending machines as required. The axes are controlled by means of line motion control. Bending roller application and material feed are controlled in combination with roller bending machines. With mandrel bending machines this comprises the bending angle, tube turning and tube intake.

|

The control offers a 12x9cm display, as well as program administration. NC programs can be created and edited directly at the control. The control is equipped with an interface for connection to an external PC or Notebook. The optional PC bending software facilitates particularly simple and convenient programming. Bending programs can be created on an external PC and transferred directly to the machine control.The NC control PP41 enables controlled and precise production of one-off and serial parts. |

Technical data

| Operator terminal | Mobile |

| Design | Modern flat design with brushed and anodised aluminium front |

| Display | 12x9cm display |

| Program administration | Yes |

| Interfaces | RS232 USB with converter |

| Positioning | Line motion controlled rapid feed – inching feed – stop |

Bending software for external PC

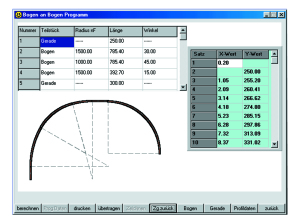

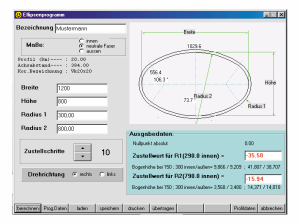

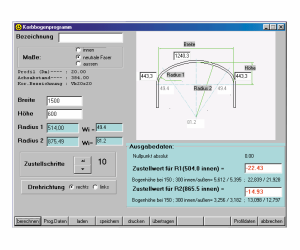

Bending software for roller bending |

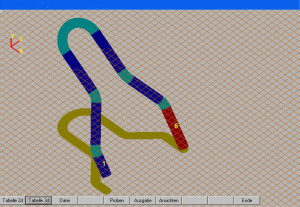

The 2D roller bending software enables targeted and precise production of roller bending parts with straight ends or multiple bending radii. The program creation is very simple and convenient. The bend radius and bend angle are entered in the program table. The contour to be bent may consist of multiple bends or straight sections. The bending contour is graphically displayed.Profile-specific sizes and elastic recovery values are logged in a material catalogue. After entering the bending contour it is possible to select the desired profile from the material catalogue. The software automatically generates an NC control program for the bending machine. The program calculation takes place with consideration to the elastic recovery, so that precise bending results and high precision are attained right away. The application of the bending roller and the profile feed takes place in multiple steps, whereby kink-free transitions are attained in the bending radii. The generated NC control program can be transferred online to the NC control PP41. The combination of NC line motion control and PC bending software significantly expands the application field and the possibilities of the bending machines. BBending contours that would only otherwise be possible on costly CNC-controlled machines can be bent in a targeted and highly precise manner. The 2D roller bending software can be installed on any commercially available Windows PC or Notebook. |