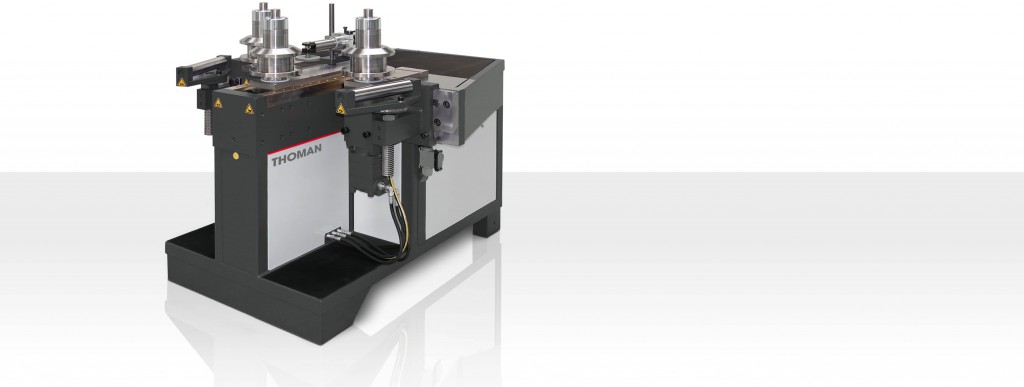

Profile bending machine RB3

powerful and extremely diverse

|

The profile bending machine type RB3 offers high bending capacity in combination with unparalleled flexibility. The high-torque, hydraulic direct drives of the profile bending machine are maintenance-free and overload-proof. Every roller is individually and directly driven. No chain drives or sliding clutches are used. The high roller bending capacity of the profile bending machine – of 7.5 kW – in combination with the high-torque direct drives also offers sufficient reserves for bending heavy-duty profiles. It is therefore possible to bend numerous bending parts to the target radius with just a single pass through the rollers. |

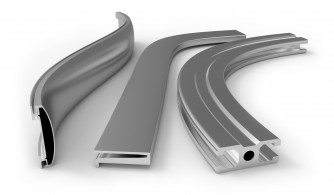

Damage to the profile is avoided, optimum bending quality is guaranteed and the maximum in productivity is attained. The application area of the profile bending machine RB3 can be expanded with a wide range of options. The machine can be equipped with a fourth roller, CNC-controlled side rollers, double rollers or a mandrel bending device. The profile bending machine RB3 offers a suitable solution for almost every bending task. The high flexibility and numerous options make the RB3 one of the most flexible and powerful profile bending machines in the world. |

APPLICATION: Metal construction, stairway construction, metalwork, machine construction, conveyance engineering, plant construction, pipework construction, façade construction, swimming pool halls, contract bending companies, utility vehicle construction

TECHNICAL DATA / CHRACTERISTICS

| Bending capacity | 7,5 KW |

| Driven rollers | 3 |

| Adjustable speed | 0-16 stepless |

| Shaft diameter | 65mm |

| Shaft length | 200mm (300mm optional) |

| Side roller spacing | 380-1100mm adjustable (min. 200mm optional) |

| X-asis stroke | 250mm |

| Pressing force | 25 tonnes |

| Weight | 1300-1500 kg |

| Connection | 400 V, 32A |

| Bending direction | away from the machine |

| Mobile machine | Optional |

| Rotation mashine | Optional |

| Automatic radius control / R-Control | Optional |

| Hydraulic support rollers | Optional |

| CNC-Controlled support rollers | Optional |